Turning and milling is a core part of our portfolio within mechanical machining.

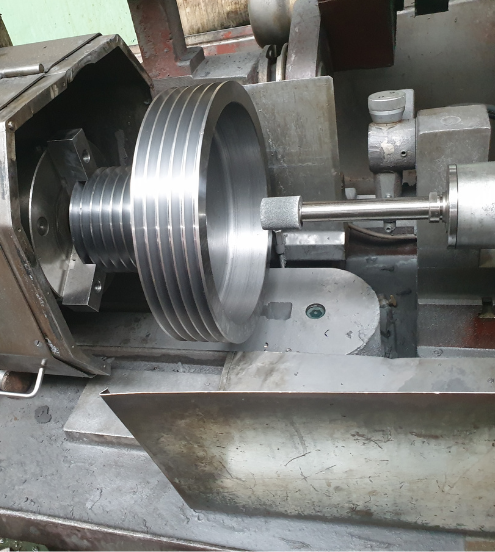

Thanks to the SU 50 NC lathe, we can turn parts up to 500 mm in diameter and up to a maximum length of 2 m above the base.

Turning can be used to produce:

• external and internal cylindrical surfaces

• external and internal conical surfaces

• flat surfaces (faces)

• shaped surfaces (cams, spherical surfaces, etc.)

Another part of our company’s comprehensive spectrum is milling.

For this purpose, we have the WMW Heckert Fräsmaschine – Vertical FSS 315 V milling cutter at our disposal. ( X=950 mm, Y=450 mm, Z=500 mm)

We are also able to provide EDM (electrical discharge machining) in cooperation.

Most commonly, moulds for pressing are produced in this way.

In cooperation, we can also carry out modern production for our clients using three-axis and five-axis machining. This technology can be used to produce parts and has therefore become dominant, for example, in the aerospace and automotive industries.

In the same way we also provide CNC machining, carousels, horizons, or even machining on automatic machines (multispindle CNC machines). The cooperation also includes zinc plating, powder coating, etc.

en

en  cs

cs de

de